Browse Challenging Surface with Confidence: Komatsu Undercarriage Parts Choice Guide

Browse Challenging Surface with Confidence: Komatsu Undercarriage Parts Choice Guide

Blog Article

Reliable Solutions: Undercarriage Components for Heavy Machinery

When it comes to hefty equipment, the undercarriage is a vital component that often establishes the general effectiveness and efficiency of the devices. Quality undercarriage parts play a substantial function in guaranteeing the smooth procedure and durability of heavy equipment. From excavators to dozers, each tool depends heavily on its undercarriage to stand up to difficult working problems. Nevertheless, wear and tear are inescapable, resulting in possible issues that can prevent efficiency and rise maintenance prices (komatsu undercarriage parts). In this conversation, we will discover the importance of buying first-class undercarriage components, typical wear obstacles dealt with by hefty machinery drivers, the advantages of timely substitutes, standards for selecting trusted providers, and crucial maintenance ideas to expand the lifespan of undercarriage elements.

Significance of High Quality Undercarriage Parts

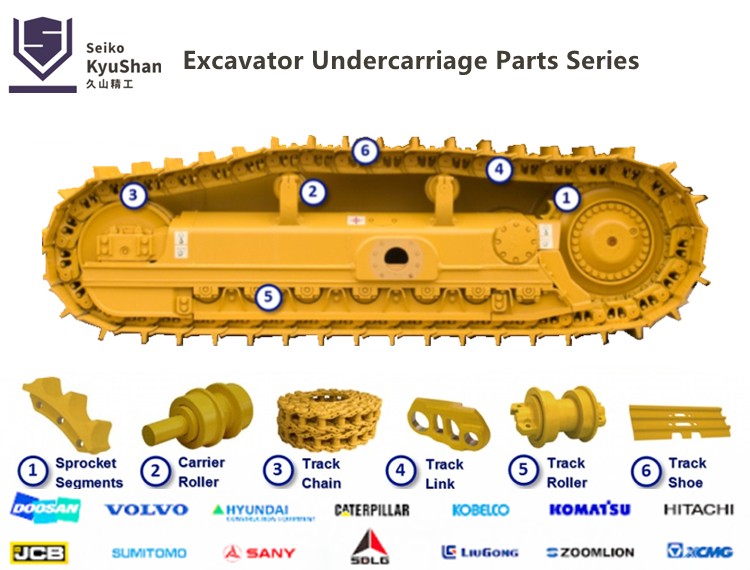

Quality undercarriage components are crucial parts in ensuring the resilience and performance of heavy machinery. The undercarriage of equipment such as excavators, bulldozers, and track loaders plays a crucial role in supporting the device's weight, offering stability on various surfaces, and soaking up the influence of irregular surface areas. By buying premium undercarriage parts, operators can considerably extend the lifespan of their equipment and minimize the danger of unforeseen break downs.

One key advantage of making use of high quality undercarriage parts is the enhancement of total equipment efficiency. Resilient tracks, rollers, idlers, and sprockets minimize friction and ensure smoother activity, eventually resulting in increased performance and effectiveness on job websites. Additionally, dependable undercarriage components decrease downtime for maintenance and repairs, permitting operators to optimize their operational hours and project deadlines.

Typical Undercarriage Wear Problems

Benefits of Timely Substitute

One trick advantage of timely undercarriage part substitute is raised equipment uptime. By changing worn parts prior to they fall short, the danger of unforeseen break downs is minimized, reducing downtime for fixings and upkeep. This positive method not just maintains the heavy machinery functional however also prevents possible damage to various other parts that might arise from a falling short undercarriage.

Furthermore, changing undercarriage components promptly can enhance total productivity. Investing in timely undercarriage component substitute is a proactive technique that pays off in terms of boosted performance and decreased operational expenses.

Picking the Right Undercarriage Supplier

Selecting the suitable undercarriage distributor is a vital decision that dramatically impacts the efficiency and maintenance of heavy equipment. When selecting a supplier for undercarriage components, a number of factors have to be taken into consideration to guarantee optimum effectiveness and cost-effectiveness. A provider that supplies a large selection of undercarriage components for various hefty machinery brand names and models can be helpful right here as it offers extra choices to fulfill particular demands.

Balancing cost-effectiveness, quality, and reliability is vital when choosing the ideal undercarriage provider for heavy equipment. By thoroughly evaluating these variables, you can choose a distributor that meets your demands and contributes to the efficient performance and upkeep of your heavy machinery.

Maintenance Tips for Extended Life-span

To make certain a prolonged lifespan for hefty machinery undercarriage components, applying an aggressive maintenance regimen is essential. On a regular basis inspecting undercarriage parts such as track chains, idlers, rollers, read review and sprockets for damage is crucial. Any signs of damage or extreme wear need to be immediately resolved to stop further wear and tear and potential failures. Additionally, maintaining the undercarriage clean from dirt, debris, and corrosive materials can significantly prolong its lifespan. Oiling moving components according to supplier referrals helps in reducing friction and prevent early wear. Monitoring track tension and alignment is additionally important to protect against uneven endure the undercarriage components. Purchasing high quality undercarriage components from reputable vendors is just as vital for ensuring longevity. By following these maintenance suggestions faithfully, hefty machinery proprietors can enhance the efficiency and toughness of their undercarriage components, ultimately decreasing downtime and operational prices.

Final Thought

In final thought, top quality undercarriage components are vital for the effective operation of heavy equipment. Choosing a dependable distributor and following appropriate upkeep practices are key to guaranteeing the prolonged life-span of undercarriage components.

Extreme wear and tear on undercarriage parts of hefty machinery can lead to considerable operational challenges and raised maintenance costs. Routine examinations, appropriate upkeep, and prompt substitutes of worn undercarriage parts are essential to reduce these common wear troubles and make sure the optimal performance of heavy machinery.

A vendor that provides a wide option of undercarriage components for various hefty machinery Discover More brands and designs can be helpful as it offers more choices to satisfy particular requirements.

By following these upkeep pointers faithfully, hefty equipment owners can enhance the efficiency and resilience of their undercarriage components, inevitably lowering downtime and functional costs.

Report this page